Making tracks - What we did this Spring

- Daniel Mason

- May 19, 2021

- 8 min read

Here at MRW we have been expectantly busy for the last few months and this is the first proper blog post for nearly 4 months. To make up for our lack of posts we wanted to summarize what we have been up to since Christmas so please enjoy a little potted history of what we have done so far in 2021.

MRW now has new members of staff joining the team, new product launches and also new machines which have broadened our inhouse capabilities. We have also been working to complete a number of orders and also produce new products some of which we will talk about below.

New employees and dispatch of order to GLMR

January saw us welcome a new employee publicly and he’s pictured above with Dan. While the snow was still settling Elly and Tom had also started to volunteer with MRW and helped us build a number of track panels. Both Elly and Tom enjoyed volunteering and wanted to come and work at MRW full time hence later in the year Tom became our very first employee and soon Elly followed. Our more temporary employee “Mr Frost'' pictured above proved to be much more temporary.

One of our larger orders we have tackled headed to Patrick Allen at GLMR who has since taken the track panels to a number of events and has many more booked for 2021 in the North of England. Be sure to drop in and see Patrick if you are in the Newcastle area at an event. Him and his team are all a very friendly bunch and only have nice things to say about MRW which brilliant!

GLMR - Portable Miniature Railway Hire UK

Tom officially joins the MRW team

Tom decided to take the plunge and come and join us here at MRW as a Craftsman who is responsible for assembly of our track panels and has since learnt every process required to make track panels from raw material to final quality check and dispatch. If you buy a MRW panel it is very likely that Tom built it.

Tom has many years experience working as a manager and leader and has helped oversee the progression of our production practices into a coherent production environment where we all are working together as a team. Tom has learnt new skills and is rapidly heading towards being able to perform every task required to make a track panel from raw material to final quality check and packing for dispatch.

New machines and tools

Prototyping is a large aspect of our products and we design and test our products in house before a customer ever gets their hands on them. Part of product development means that we utilise a wide variety of tools to remove or add metal and other materials. One of the machines we had in Norfolk for this purpose was a Bridgeport Milling machine and after agreeing to bring it up to Nottingham the task came to move it out of the Garage along the drive and up onto the trailer ready for it’s journey west.

The Mill weighs a tad over 1 tone with its head attached so the first task was to remove this with block and tackle which made the task of moving the base much simpler as it removed about 400kg and significantly reduced the centre of gravity.

After bringing the base of the machine in front of the trailer we then jacked it up inch-by-inch to achieve the required height to then drag it into the trailer along the steel work used for the loco ramp.

All went without a hitch and we also managed to dodge the showers which made the whole day much more enjoyable. Back at MRW the task of re-assembly was much simpler with the aid of a forklift to remove the machine from the trailer and then again to lift the head back on to the mill.

The Mill is now set up and in regular use in the workshop. This means we are able to tackle some contract Machining work and also machine parts in house for various projects.

Cold cut saw

The new saw is here and ready for business! Part way through April our bandsaw’s motor started to pour out smoke and gave up the ghost. This led us to need a replacement and also an upgrade. We purchased this hefty circular saw to help us achieve an accurate reliable cut for our box steel.

Above a little video of the saw guard in use.

We have all gotten our hands on the new saw cutting rails and other bits of steel for manufacture.

So far the saw has proved to be invaluable in achieving a good cut and has significantly improved our production time.

Putting in the overtime

We often work weekends and Easter was no exception,

During the Easter brake we came in to make more track for various costumers but also took a moment to test out the track and also have some fun!

Built to LAST !

More of us are working here at MRW and we need better workbenches to build track panels on. After some discussion it was agreed to build from scratch to ensure we had a strong and sturdy workbench that would last for years. The build also gave Elly and Tom a chance to try out their welding skills on a real life project.

The pictures speak for themselves but we still have another coat of paint to go on before it's finished.

Collection of close up photos of the new workbench before installation in the workshop

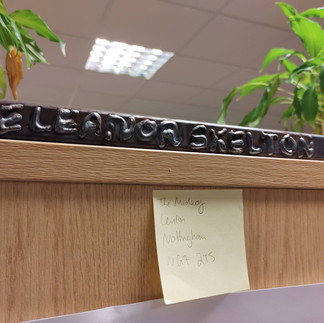

Elly joined the team

Elly (Design-Maker) and Tom (Craftsman) have joined us during the start of 2021 and have proved invaluable when progressing the orders we have had this year. Elly brings with here a wide skill set but is especially experienced with Computer Aided Design (CAD). We have put Elly’s skills to good use with our design of a new enclosure to drill sleepers inside and a welding jig for custom curved panels.

After an introduction to welding Elly has practiced her skills to be a very competent welder.

Woolsey points

The Woolsey Miniature Railway is another new portable miniature railway that is now using MRW portable track. They took delivery of their fist sections in June 2020 but have had to wait some time to actually use it with real passengers due to lockdowns. In Janary 2021 they decided to purchase a set of MRW portable points and these proved to be the first production points that have left MRW. The Woolsys have used and tested the points not only with there own trains but with passengers riding. Following on from there feedback and experiences we are looking to make some refinements to the design but here at MRW we have been unbelievably pleased with how well the points have performed and are in the middle of manufacturing more.

Woolsey's Miniature Railway is a Non-Profit Organisation who are offering a portable track hire at events to raise money for local charities. For more info about the WMR head over to there website https://www.woolseysminiaturerailway.com/about

To find out more about the portable points see our website page https://www.miniaturerailwayworkshop.com/product-page/points

One of the design requirements was that the points should be trailable and we are pleased to show the results of our in house testing.

New Products

Vallorbe Swiss Made Metalworking Files

Photos of the brand new files and some of the ones we have been using here at MRW.

We have been looking for a number of months to find a reliable manufacturer of metalworking files to use in our production of portable track. We have been putting a set of Vallorbe files through their paces filing our mild steel day in day out. Even after weeks of continued heavy use the files remain sharp with a very good cutting face.

Edging strip and stakes

Our plastic wood manufacturers have come up with this product for use in gardens to edge paths and flower beds but we thought it would be perfect to hold back Ballast on a Miniature Railway. It's surprisingly flexible whilst also holding its shape well. The stakes match the strip to allow you to dig it into the ground to give a firm separation between track bed and surrounding area.

Our plastic wood edging has been sent out to various customers for testing on real miniature railways. He is what Foz Fosdike has to say:

Ta da 🎉 Simply put, it’s edging strip! A recycled plastic “wood” strip and stakes which are a maintenance free solution for edging miniature railways! You’ll have likely seen the odd video (and I mean that in the truest sense) on Miniature Railway Workshops social media outlets of this new product (as I did) but it’s hard to get a sense of what it’s like in the real world, my first impressions from the videos were that’s it’s a bit small and a bit flimsy... well I’m happy to take those presumptions back 😁 this is an ideal size and perfectly sturdy for ballast retention whether it’s fully installed in the ground or partially raised out of the ground 👍 it cuts and drills just like wood (with the advantage of less fine particulate dust) and doesn’t need treating! Very much looking forward to giving this a go! This isn’t your ordinary lawn edging (ordinary lawn edging also pictured for comparison). Looking forward to trying this out!

To buy your own head over to

https://www.miniaturerailwayworkshop.com/shop

Sleeper lengths

We now stock two sizes of plastic wood lumber suitable for miniature railway sleepers.

20x60x1500mm (1.5M)

Ideal for portable miniature railways due to its light weight (1.70kg per 1.5m length) and its slim profile which helps reduce the height of track when stacked.

30x60x1500mm (1.5M)

Being slightly thicker this wood is perfect for permanent railways as it gives more material to screw self tappers into and also has greater depth to help hold the track in the ballast.

Photos of the Plastic wood in use at the Flair Light Railway

More info https://www.miniaturerailwayworkshop.com/pro.../plastic-wood

More than just track

We have partnered with Abbots Model Engineering (AME) to supply a complete railway package including everything you need to start out in this hobby. Abbots have been making electric locos to a high standard since 2003. We have had personal experience with Abbots and knew their locos would be the perfect accompaniment to our track. We now can provide a loco, rolling stock and track all through one point of communication. We hope to help guide new people who are interested in joining the hobby as to the best products to suit their individual needs. We can also reduce postage costs for our customers with one recent order being of note that was dispatched to Scotland on one pallet saving the buyer considerable expense and giving a complete railway arriving at his doorstep.

More info about Abbots Model Engineering www.ametrains.co.uk

Pictures of our first pallet to Scotland and our first order to go out of our complete railway package!

- Electric Loco (kit form Neptune 3 from Abbot's)

- Riding Truck (ready to run carriage from Abbot's)

- Straight Jubilee Track Panels (MRW)

- Buffer Stops (MRW)

- Coupling Bars and Coupling Pins (MRW)

We are still in the process of updating the website to include more of Abbots Model Engineering products but we are excited to say we are effectively able to offer the complete Abbots range.

Part dispatch of a complete railway

A complete miniature railway to encompass a hole house.

We have had the pleasure of working with a customer to deliver a complete railway to encompass his house. The last few months have stretched our production with panels of all shapes and sizes being made for various orders and so far we have made all of the straights for the order but the curves are still in manufacture.

The straits where dispatched earlier this month and our MD Dan plans to take the remaining curves down to the customer latter this month personally.

This is a really exciting project to be involved with and we are very pleased to be able to offer this complete railway albeit with a slightly longer lead time than we would have liked.

Where next?

We have a host of new projects that are coming to fruition some track items but many products unrelated to track also.

The best way to keep up to date is to follow us on Facebook as we regularly post there, but we will also endeavour to give your regular updates on this blog.

Looking for more info about portable track or MRW products in general? Contact us by using the inbuilt web chat, Tel: 07591 006642 or Email: miniaturerailwayworkshop@gmail.com

Comments